Buy the + trailer tyre for long-haul efficiency with low rolling resistance, exceptional mileage and even wear, robust damage resistance and a retreadable casing to reduce your total cost per km.

Low-profile trailer architecture. Designed for low-deck, high-volume semi-trailers, the Michelin XTA2++ leverages a low-profile geometry to reduce coupling and load-bed height, lowering the centre of gravity for superior straight-line stability and roll resistance while maximising cubic capacity within legal height limits. The reduced frontal area and improved airflow around the underbody cut aerodynamic drag, while the broad, square footprint distributes load over a larger contact patch to keep contact pressures low, improving wear life and protecting road surfaces. This architecture also improves rolling resistance by reducing casing deflection at the shoulder, supporting lower fuel burn and CO2 output for linehaul operations.

Fuel-efficient tread compound. A low-hysteresis rubber matrix with a high-dispersion silica/carbon black blend minimises internal energy loss in the Michelin XTA2++, keeping operating temperatures stable under sustained motorway speeds and high axle loads typical of tri-axle trailers. The compound’s optimised glass transition temperature balances wet grip with minimal rolling resistance, while advanced coupling agents strengthen polymer–filler bonding to resist tear, chunking and scrub. The result is quantifiable fuel savings over long routes without compromising abrasion resistance, enabling fleets to lower total cost per kilometre and emissions simultaneously.

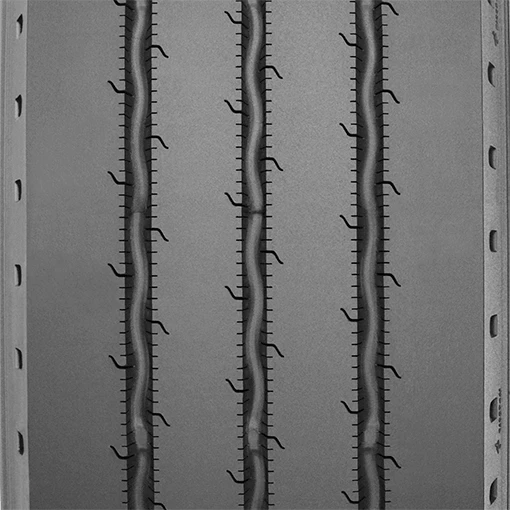

Even-wear rib geometry. The Michelin XTA2++ employs a multi-rib, straight-groove pattern with reinforced tie-bars and a decoupling groove to control block movement and suppress heel-and-toe wear caused by lateral scrub on tight manoeuvres. An engineered contact-pressure distribution across the tread width reduces shoulder overload on multi-axle trailers, while groove wall angles and tread stiffness gradients are tuned to maintain rib integrity under side loads. This delivers long, even mileage, consistent tracking, and clean wear patterns that improve regrooving precision and extend usable life.

Heavy-duty casing construction. A robust, cool-running casing with high-tensile steel belts, fatigue-resistant cord angles and reinforced chafer zones equips the Michelin XTA2++ for high-load, high-scrub trailer service. The bead area features a stable apex and strong bead bundle for secure seating on modern rims, improving bead endurance under repeated torsional loads from docking and yard turns. Efficient heat evacuation through the belt package limits thermal stress, protecting the ply coat and belt edges to enhance retread acceptance and longevity through multiple Michelin Remix lives, reducing downtime and whole-of-life cost.

Confident wet-road grip. Four wide circumferential channels and directional lateral groove geometry evacuate water rapidly from the contact patch, maintaining a high local friction coefficient on wet chipseal and smooth asphalt common across New Zealand routes. Micro-siping on the rib edges promotes edge effect at low slip ratios for predictable braking and lane-keeping, while the tread’s stiffness map preserves footprint shape under load to avoid hydrodynamic lift at highway speeds. The result is controlled stopping distances and stable tracking in wet conditions without sacrificing fuel efficiency or wear performance.

19.5"